Sales Order Processing case study

Engineering Sales Order Processing case study

The customer, a comprehensive professional services firm providing design solutions to private and public sector clients, required an efficient sales order processing system integrating with Deltek Vision. Key requirements included: billing interface with Vision, accounts payable interface via invoice matching, strong control over product item master records, including complex bill of material assembly.

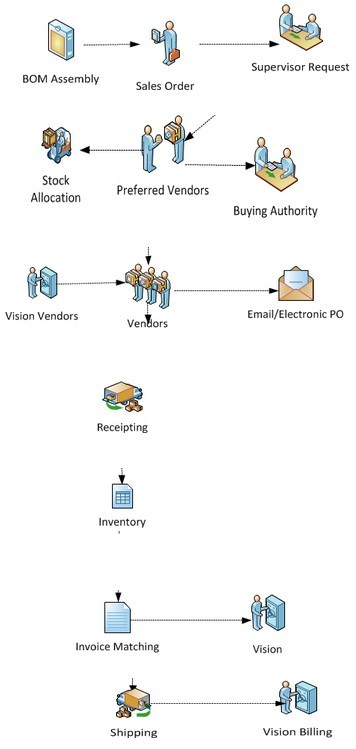

Sales Order Processing

Sales Order Processing flow chart

The sales order can be made up of many combinations of assemblies, items and services. As a user constructs the sales order the system provides real time control over margins and build specifications. The system allowed an easy set up of all required parts and a straight forward authorisation trail.

Fulfilment: purchase or stock

The purchase order will be automatically routed to the preferred vendor for the associated items within the bill of assembly. Vendor selection can be overridden on the sales order if required. The user can also select the item to come from stock, selecting a specific batch quantity or serial number to be added to the packing list. Any final purchase orders will be emailed to the vendor once any authorisation has been completed.

Purchasing

Vendors receive the purchase order by mail or by email. A system alert manager monitors the progress of the purchase against the required delivery dates. Purchase order amendments can be raised at any time. Utility bills and other contracted costs can also be entered as purchase contracts.

Goods receipt

Each category of product has its own set of attributes to be used when recording the eventual receipt of the goods or service. Any serialised item can have make, model, year of manufacture, serial number or any other items captured by electronic entry, manual entry or through the punch-out service.

Equipment and inventory

Any IT equipment is logged into the physical asset register passing on all of the prior information collated to date. The Equipment system allows for asset tracking and automatic reconciliation with the Fixed Asset register.

Invoice matching

Vendor invoices can now be easily matched (two, three or four-way) against the system. The batch of vendor invoices are automatically generated into the Vision Accounts Payable system. Any variances, subject to route and category limits, will automate the production of a new purchase order change request.

Shipping/billing

All part/full shipments will generate a billing entry in Vision with the correct sales order references, quantity and values. Shipping documents can be formatted and templated by the system.